Haicheng Pai Lou town developed Mining Co., Ltd.

Address: No. 1059, Pai Lou village, Pai Lou Town, Haicheng.

Telephone:15841201000Mr. Hu

mailbox:1561481033@qq.com

Q Q:1561481033

Website:sjgrc.cn

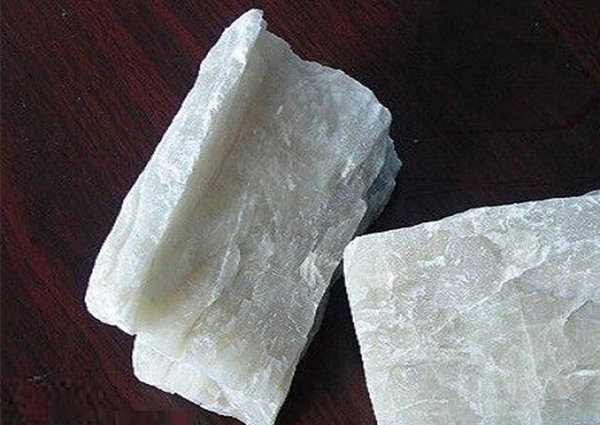

By mixing light-burnt magnesia powder, magnesite particles and water in different proportions and forming into cylindrical specimens by hydraulic pressure, the effects of different proportions and forming pressures on the physical and chemical properties of the specimens are discussed through experimental analysis. The content of M g O and the reduction of ignition in the specimens can be adjusted by using different proportions of light-burnt magnesia powder and magnesite particles to meet the requirements of different steel plants. The process of magnesia slagging and the need of furnace protection for converter.

Light-burned magnesia ball is mainly used in converter steelmaking with magnesium slagging process. The use of light-burned magnesia ball with magnesium slagging can provide sufficient active MgO to slag, inhibit the dissolution and diffusion of MgO to slag in lining, reduce lining erosion, protect lining and increase furnace life.

In recent years, the National Experimental Research on light-burnt magnesia spheres is gradually deepening. Now the following steps are mainly taken to test and study light-burnt magnesia spheres.

1 test

1.1 raw materials for trial

1.2 sample preparation and testing

2 results and discussion

Effect of 2.1 addition of light burned magnesia powder on apparent bulk density of samples

2.2 effect of water addition on apparent bulk density of samples

2.3 effect of forming pressure on apparent bulk density of samples

2.5 effect of water addition on compressive strength of specimens

2.6 effect of forming pressure on compressive strength of specimens

2.7 changes in moisture content (water / dry matter) of samples

2.8 test of physical and chemical properties of samples

3 conclusion

1) Adding some magnesite particles to the light-burned magnesia powder can improve the apparent bulk density and strength of the sample.

2) the apparent bulk density and strength of the sample were larger when the amount of water addition / light burned magnesia powder was 15% to 20%.

3) the apparent bulk density of the sample increases with the increase of molding pressure.

4) The apparent bulk density of the moulded sample is close to the apparent bulk density of the sample dried after two days'natural placement in air, and the free moisture is less than 1%, and the combined moisture is 5%-6%.

Haicheng Pai Lou town developed Mining Co., Ltd.

Address: No. 1059, Pai Lou village, Pai Lou Town, Haicheng.

Telephone:15841201000Mr. Hu

mailbox:1561481033@qq.com

Q Q:1561481033

Website:sjgrc.cn

Haicheng Shida Refractories Co., Ltd. Copyright All Yingkou Zhongchuang Network Technology Co., Ltd. Provides Technical Support